When you

add Cummins injectors to your vehicle, you need to know how to properly

maintain them in order to get the best out of them. Knowing the problems to

watch for as well as the right way to address them can help you avoid machine

downtime as well as expensive equipment failures.

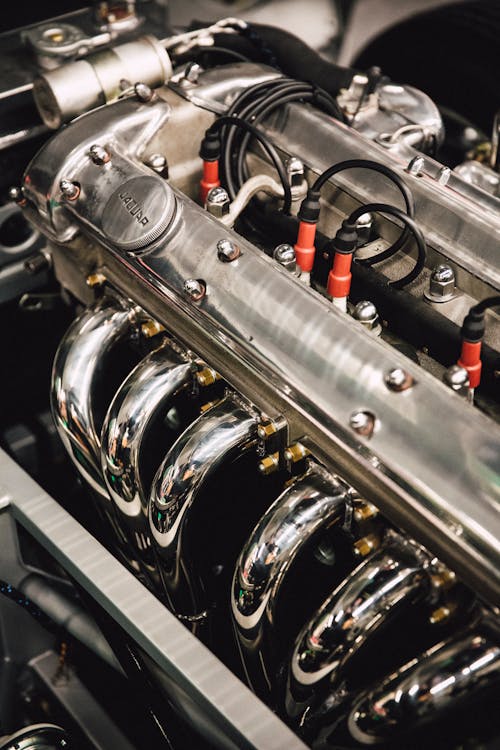

So how do the Cummins injectors work? These

injectors pressurize diesel fuel and pump it through a fixed or electronically

controlled opening. This causes fuel to be delivered to the engine as a spray

or fine mist, which is easier to ignite compared to a heavy, solid stream. The

mist burns more evenly and efficiently.

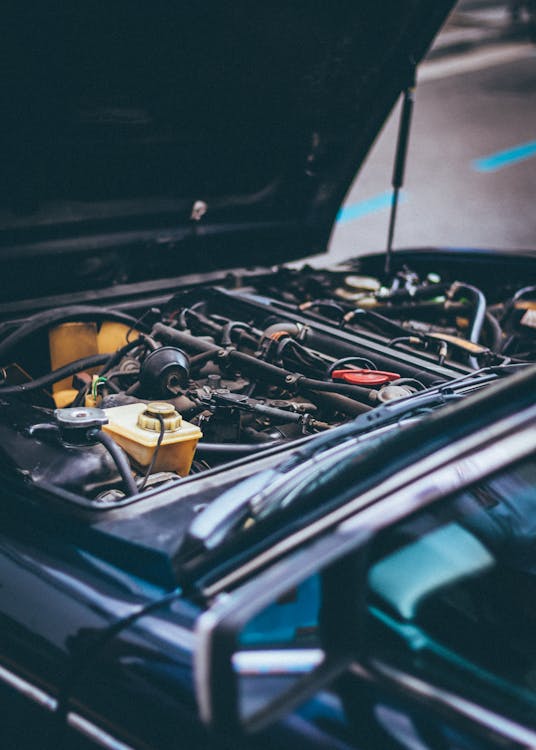

If you do

not maintain your Cummins

injectors properly, the process becomes less effective, and it could even

lead to a full engine breakdown. Among the most common issues that negatively affect

diesel fuel injection systems include clogged or dirty fuel injectors and air

or water into the fuel injection system.

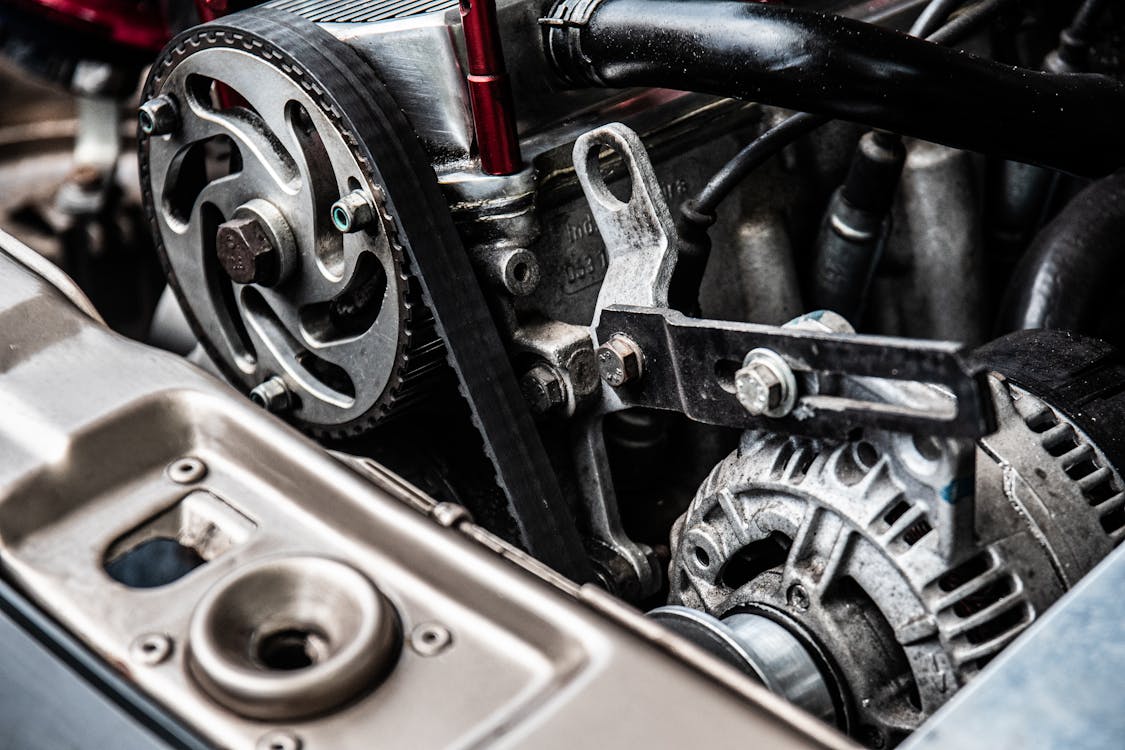

Before the

abovementioned issues are checked for and addressed, safety precautions need to

be taken in order to avoid injury. It is recommended to depressurize the diesel

fuel injection system before any maintenance work is done. Since diesel fuel is under high amounts of

pressure when operating, it is important to allow your engine to completely

cool and depressurize the fuel injection before any type of maintenance is

done. By doing so, you will project

yourself from dangerous sprays of fuel when removing the fuel filter.

There are various signs that you can look for

to know that your Cummins injectors are clogged or dirty. Some of them include rough idling, throttle

hesitation, hard starting, decreased fuel mileage, black smoke from the exhaust

manifold and pinging sounds.

For more tips on how to maintain Cummins injectors, visit our website at https://puredieselpower.com/